Unveiling FRP Pultruded Profiles: A Versatile Material Beyond "Light" and "Strong"

When you hear the word "Fiberglass Reinforced Plastic" (FRP), you might first think of sculptures or ship hulls. But today, we'll introduce FRP pultruded profiles, a discreet yet powerful member of the FRP family. With its unique process and superior performance, it's quietly replacing traditional metals and wood, becoming the new favorite in numerous industrial sectors.

I. What is FRP Pultruded Profile?

Simply put, it's a high-strength composite material produced continuously, like noodles.

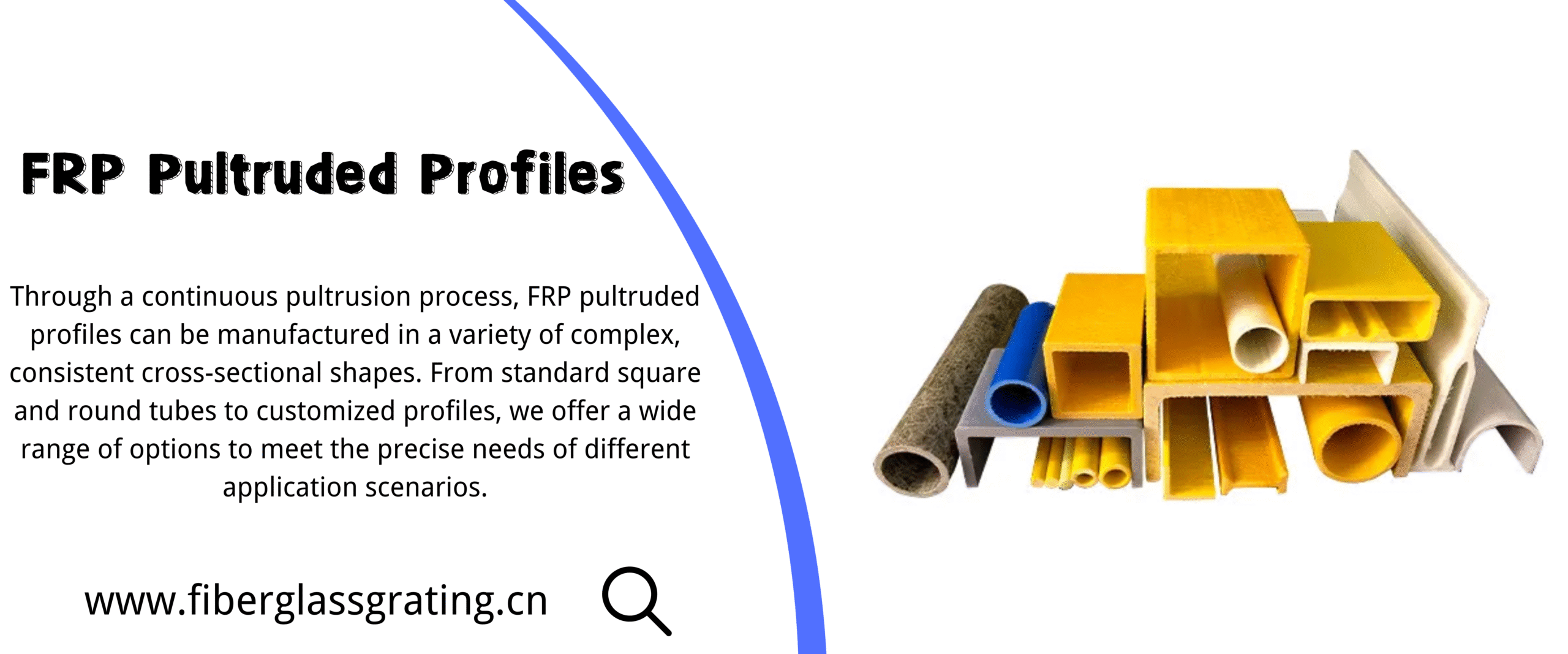

The core process is pultrusion: resin-impregnated glass fiber rovings, continuous mats, and other reinforcing materials are pulled through a heated, custom-shaped die under traction. After curing and cutting, they are finally formed into a profile with a fixed cross-section.

This process contributes to its exceptional performance, unlimited length, and consistent quality.

II. The Outstanding Performance of FRP Pultruded Profiles

Why is it so popular? Because it perfectly combines several excellent properties:

Lightweight and High-Strength: It weighs only one-quarter of steel and two-thirds of aluminum, yet its strength rivals that of high-grade alloy steel. This means significantly reduced structural weight, transportation, and installation costs.

Corrosion-Resistant and Long-Lasting: This is one of its core advantages. It withstands the erosion of acids, alkalis, salt, moisture, and harsh atmospheric environments, and never rusts. It is particularly suitable for corrosive environments such as chemical, water treatment, and marine applications, with a lifespan exceeding 20 years.

Excellent Electrical Insulation: It is non-conductive, making it an ideal insulating material for ladders, guardrails, cable racks, and other electrical equipment, ensuring safety and reliability.

Easy to Design: By changing the mold, it can extrude nearly any desired constant cross-sectional shape, offering tremendous design flexibility.

Low-Maintenance: The surface is smooth, and the color can be adjusted using color paste. It is resistant to fading, requires no paint, and is virtually maintenance-free.

Aging Resistance: The addition of UV inhibitors effectively resists aging, allowing for long-term outdoor use.

III. What are the characteristics of FRP pultruded profiles? (Complete Product Range)

Fiberglass pultruded profiles come in a wide variety of shapes, reproducing the cross-sections of nearly any traditional metal profile. Here are some of the most common and widely used types:

- Bars and Rods

Round Bars: Commonly used to make bolts, nuts, insulating rods, fishing tackle, etc.

Square/Rectangular Bars: Used for structural support, reinforcement, etc.

- Sheets and Strips

Flat Sheets: Used for equipment guards, load-bearing plates under gratings, operating platforms, etc.

Corrugated Sheets: Often combined with flat sheets to form the webs of I-beams and channels for enhanced stability.

- Structural Profiles (This is the most widely used type)

Equal/Unequal Angles: The most widely used, used to construct frames, towers, and structural reinforcements, such as cooling tower frames.

Channels: Used for rails, slides, brackets, frames, etc.

I-Beams: With their high load-bearing capacity, they are the primary structural load-bearing beams.

Square/Rectangular Tubes: Widely used in building structural frames, guardrails, handrails, and tent poles.

Round Tubes: Commonly used in fluid conveying pipelines, structural columns, flagpoles, and more.

- Specialty Profiles

Pultruded Grating: Assembled from pultruded rectangular bars or "I" profiles, it is non-slip, lightweight, and an excellent alternative to metal grating.

Cable Trays/Ladders: Designed specifically for the power industry, it offers excellent electrical insulation and corrosion resistance.

Photovoltaic Solar Mounting: Corrosion-resistant and maintenance-free, it is a reliable long-term option for photovoltaic power plants.

Window/Door Frame Profiles: Offer excellent thermal insulation (low thermal conductivity) and can be made into energy-saving windows and doors.

Highway Guardrails/Sidewalk Guardrails: With their eye-catching colors and excellent weather resistance, they add a touch of urban beauty.

Pasture/Farm Profiles: For example, railings and feed troughs, they are resistant to corrosion from livestock manure.

Custom Profiles: Any profile with a special cross-section manufactured according to customer drawings, such as specialized guide rails, sealing strip bases, etc.

IV. Where are they used? (Application Areas)

Due to their diverse performance, FRP pultruded profiles are used almost everywhere:

Construction: Cooling tower structures, roof decking, door and window profiles, handrails, and awning frames.

Chemical Processing: Operating platforms, stairs, handrails, guardrails, equipment supports, and structural components for corrosive environments.

Power and Energy: Cable trays, insulating ladders, transformer partitions, power guardrails, and photovoltaic mounting systems.

Transportation: Automotive lightweight components, subway/train interior panels, luggage racks, and internal bumper reinforcement beams.

Municipal Environmental Protection: Water treatment plant scraper components, gratings, guardrails, and pedestrian bridge structures.

Marine: Dock guardrails, ship structures, and fish farm facilities.

Leisure and Entertainment: Tent poles, park benches, and amusement equipment structures.

V. How to Choose the Right FRP Pultruded Profile? When choosing, please consider the following:

Resin Type:

Isophenyl unsaturated polyester resin: General-purpose, with excellent weather resistance.

Vinyl ester resin: Top-tier corrosion resistance, suitable for strong acid and alkaline environments.

Reinforcement: The type and content of glass fiber directly impacts strength.

Cross-sectional shape and size: Select the most appropriate profile based on the structural load requirements.

Surface treatment: Whether a non-slip sandblasted surface, UV protection layer, etc. are required.

Conclusion

Fiberglass pultruded profiles, a versatile material, offer irreplaceable performance advantages, providing safer, more economical, and more durable solutions for modern industrial design and manufacturing. If your project faces challenges related to corrosion, weight, insulation, or maintenance, consider this versatile profile; it may be the answer you're looking for.