Definition and Overview

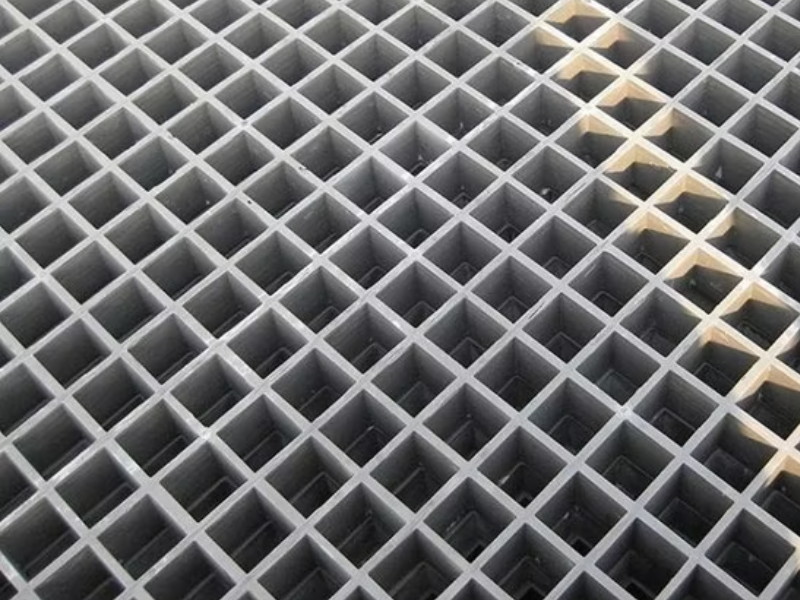

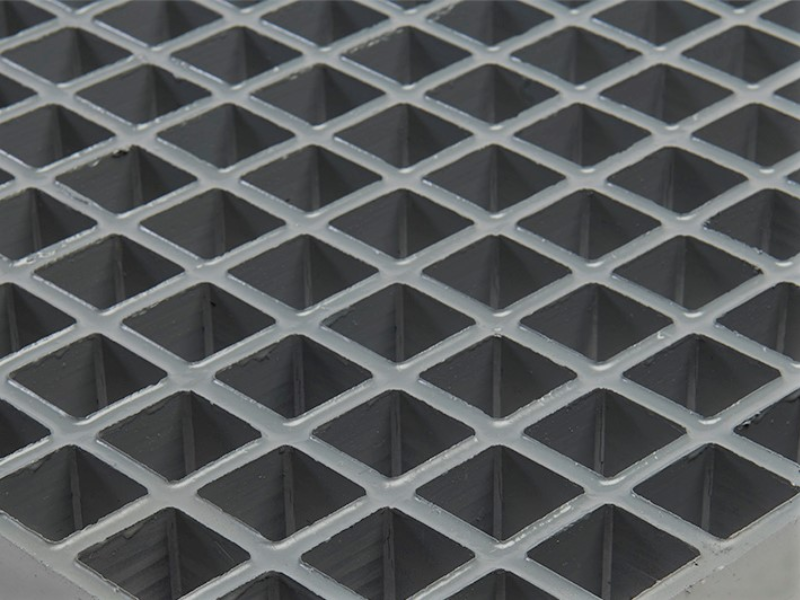

FRP molded grating is a mesh plate or structural part made of glass fiber (reinforcement material) and unsaturated polyester resin (matrix material) as the main raw materials, through a molding process.

It is one of the main types of composite material (FRP - Fiber Reinforced Plastics/Polymer) grating (the other is pultruded grating).

Its design simulates the traditional metal grating structure, with regular load-bearing bars (usually I-shaped or rectangular) and transverse connecting bars to form a uniformly distributed grid.

The core value lies in excellent corrosion resistance, light weight and high strength, insulation, flame retardant, anti-slip, maintenance-free and other characteristics, making it an ideal choice for corrosive environments, places with high lightweight requirements and strict safety requirements, replacing traditional materials such as metal and wood.

Core Materials

Reinforcement materials: Mainly alkali-free glass fibers, including resins, yarns, etc. Provide strength and stiffness of the grating. The direction and distribution of the fibers are critical to performance.

Matrix materials: Unsaturated polyester resin is the most commonly used. Depending on the application requirements, vinyl ester resin (stronger corrosion resistance), epoxy resin (better mechanical properties) or modified resin (such as flame retardant resin, weathering resin, etc.) can also be selected. The resin binds the fibers into a whole and imparts corrosion resistance, weathering resistance and other properties.

Fillers/Additives: Mineral fillers (to reduce costs and improve processability), color pastes (to provide color), flame retardants, UV stabilizers, etc. may be added to meet specific performance requirements.

Manufacturing process - compression molding

Key process: This is the core process that distinguishes it from other FRP gratings (such as pultruded gratings).

Mold preparation: Use high-precision, high-strength metal molds (usually steel molds), and the mold cavity determines the shape, mesh size, thickness, etc. of the grating.

Material laying: The mixed resin mixture (containing resin, initiator, accelerator, filler, etc.) and the cut glass fiber mat/cloth are alternately laid in the lower mold cavity of the mold. Precisely control the resin content and fiber distribution.

Mold closing and pressurization: The press knife is pressed down, applying a certain pressure (one of the core features of molding) and temperature (usually heating is required). The pressure allows the resin to fully infiltrate the fiber, expel bubbles, and compact the material.

Curing and molding: The resin undergoes a cross-linking reaction and solidifies at the set temperature and pressure for a period of time.

Demolding and trimming: After the curing is completed, the mold is opened, the molded grid plate is taken out, and necessary post-processing such as trimming and grinding is performed.

Post-curing (optional): Sometimes additional post-curing treatment is performed to increase the degree of complete curing.

Process characteristics:

Accurate size and good surface quality: The mold ensures shape and size accuracy, and the surface is smooth or has a designed anti-slip texture.

High production efficiency: Suitable for mass production.

Excellent mechanical properties: Pressure molding allows the fiber to be more fully infiltrated, the product has high density, and good strength and stiffness.

Strong designability: grilles and special-shaped parts (such as stair treads, cover plates, tree grates, etc.) of various sizes, thicknesses, and grid shapes can be easily produced through molds.

Main Features And Advantages

Excellent corrosion resistance: It can withstand most chemical media and harsh environments such as acids, alkalis, salts, solvents, seawater, and humidity. It will not rust or corrode, and has a long service life (usually more than 20 years). It is the first choice in the fields of chemical industry, ocean, and sewage treatment.

Lightweight and high strength: The density is only about 1/4 of steel and about 2/3 of aluminum, but the strength is close to that of ordinary carbon steel. It is easy to transport, install, and cut, reducing the load of the supporting structure and the installation cost.

Excellent anti-slip performance: The molding process can accurately produce various convex or sand surface anti-slip effects (usually the surface is covered with a sand-containing resin-rich layer), which can provide a safe and reliable walking surface even in oily and humid environments.

Good insulation performance: Excellent electrical insulation, no electromagnetic induction, suitable for substations, electromagnetic sensitive areas, flammable and explosive places.

Flame retardant: Different levels of flame retardant requirements (such as ASTM E-84 Class 1) can be achieved by selecting flame retardant resins to improve fire safety.

Maintenance-free and long life: No need for regular anti-corrosion coating like steel, almost no maintenance, and low comprehensive use cost.

Good fatigue resistance: Stable performance under long-term dynamic load.

Good design flexibility: Customizable colors (commonly used yellow, green, gray, red, etc.), size, shape, thickness, grid size (such as 38x38mm, 50x50mm) can be designed according to needs.

Safety and environmental protection: No harmful substances are released during production and use (comply with RoHS requirements, etc.), and can be recycled.

Comparative advantages with traditional Grating materials vs steel Grating:

corrosion-resistant (no maintenance required), lightweight (saving installation effort and cost), insulation, better anti-slip properties (especially in slippery environments), non-magnetic, and long life (in corrosive environments).

vs aluminum grille: corrosion-resistant (especially alkali-resistant), higher strength, usually lower cost, and insulation.

vs wood grille: corrosion-resistant, insect-proof, flame-retardant, high strength, long life, and maintenance-free.

vs concrete: lightweight, fast installation, strong designability, impact resistance (not easy to break), and insulation.

Application Fields (extremely wide)

Petrochemical: Platforms, walkways, equipment platforms, trench covers, fences, stair treads (special design required).

Offshore platforms and ships: decks, gangways, walkways, helicopter platforms, mooring platforms.

Sewage treatment/water treatment: operating platforms, walkways, covers, aeration tanks, maintenance channels, biofilters.

Power: substation grid plates, cable trench covers, insulating walkways, cooling tower platforms.

Papermaking: walkways, platforms, bleaching towers in wet and corrosive environments.

Metallurgical mines: pickling workshops, electroplating workshops, beneficiation platforms, sieve plates (specific types).

Food and beverage: production workshop platforms, equipment platforms, and cleaning area walkways that meet hygienic requirements.

Transportation: bridge sidewalks, maintenance roads, train/subway platform walkways.

Municipal construction: pedestrian overpasses, green belt tree grates, ditch covers, car wash grilles.

Electronics: clean workshop elevated floors (specific types), anti-static areas.

Others: industrial plants, commercial buildings (such as shopping mall rooftops), agricultural breeding, zoo fences/pedalboards, etc.

Precautions For Purchase And Use

Clear requirements: Determine the use environment (corrosive media, temperature, humidity), load requirements (uniformly distributed load, concentrated load), mesh size, thickness, surface treatment (anti-slip requirements), color, flame retardant grade, electrical performance requirements, etc.

Resin type: Select according to the corrosive environment (polyester, vinyl ester).

Thickness: directly affects the load-bearing capacity.

Grid size: affects the through-hole rate and the requirements for falling object protection.

Load-bearing bar height/section: determines the main load-bearing capacity (commonly used 25mm, 38mm, 50mm high).

Barcol hardness: reflects the degree of curing and surface wear resistance.

Correct installation: Use matching FRP or metal (need to be isolated) fasteners (clips, U-shaped nails, bolts, etc.), ensure that the support spacing meets the design requirements, and pay attention to protection (dust) when cutting.

Maintenance: Although maintenance-free, regular cleaning (clean water or mild detergent) helps maintain appearance and service life. Avoid long-term heavy impact or extreme high temperature (exceeding the thermal deformation temperature of the resin).

FRP molded grating has demonstrated strong competitiveness and irreplaceability in many industrial, municipal and commercial fields due to its unique composite material properties (corrosion resistance, light weight and high strength) and advanced compression molding process (precise size, excellent performance, flexible design). It solves the pain points of traditional materials in terms of corrosion, insulation, lightweight, safety and anti-slip, and maintenance costs. It is an efficient, safe, durable and economical long-life solution. With the continuous advancement of material technology and processes, its application prospects will be broader.

Resin Type

FRP Grating Surface Type

It's flat and smooth, with no grain or texture, and feels like hard plastic.

Safe and anti-slip by embedding wear-resistant particles on the grating surface

The design with regular depressions enhances anti-slip and drainage performance.

The surface particles form a uniform and dense rough surface

The design with regular depressions enhances anti-slip and drainage performance.

Fiberglass Grating Cutting Methods

Product Benefits

A: FRP grating is a grid-like plate made of glass fiber as reinforcement material and unsaturated polyester resin as matrix through special process. It has the characteristics of corrosion resistance, light weight and high strength, flame retardant, insulation, anti-slip, etc., and is widely used in chemical industry, electric power, sewage treatment, platform walkway and other scenes.

A:

1. Dimensions (length, width, and thickness)

2. Load requirements (such as vehicle tonnage)

3. Operating environment (corrosive media/temperature)

4. Surface type (glossy/sanded)

5. Color and flame retardant requirements

A: Conventional colors (yellow, gray, green) do not affect strength, but dark colors (such as black) are better for UV resistance and are recommended for long-term outdoor use.

Are you looking for a reliable FRP Grating and Moulding supplier?

As a high-quality supplier who has been deeply involved in the FRP industry for many years, we focus on the research and development and production of FRP gratings, FRP pultruded gratings, FRP pultruded profiles and matching FRP grating molds. With advanced technology, stable quality and professional services, we have become a long-term partner of many engineering companies, equipment manufacturers and end users.If you are looking for a stable, professional and reliable FRP product supplier, please contact us! We will provide you with the most competitive products and services to help your project land successfully!