Definition and Overview

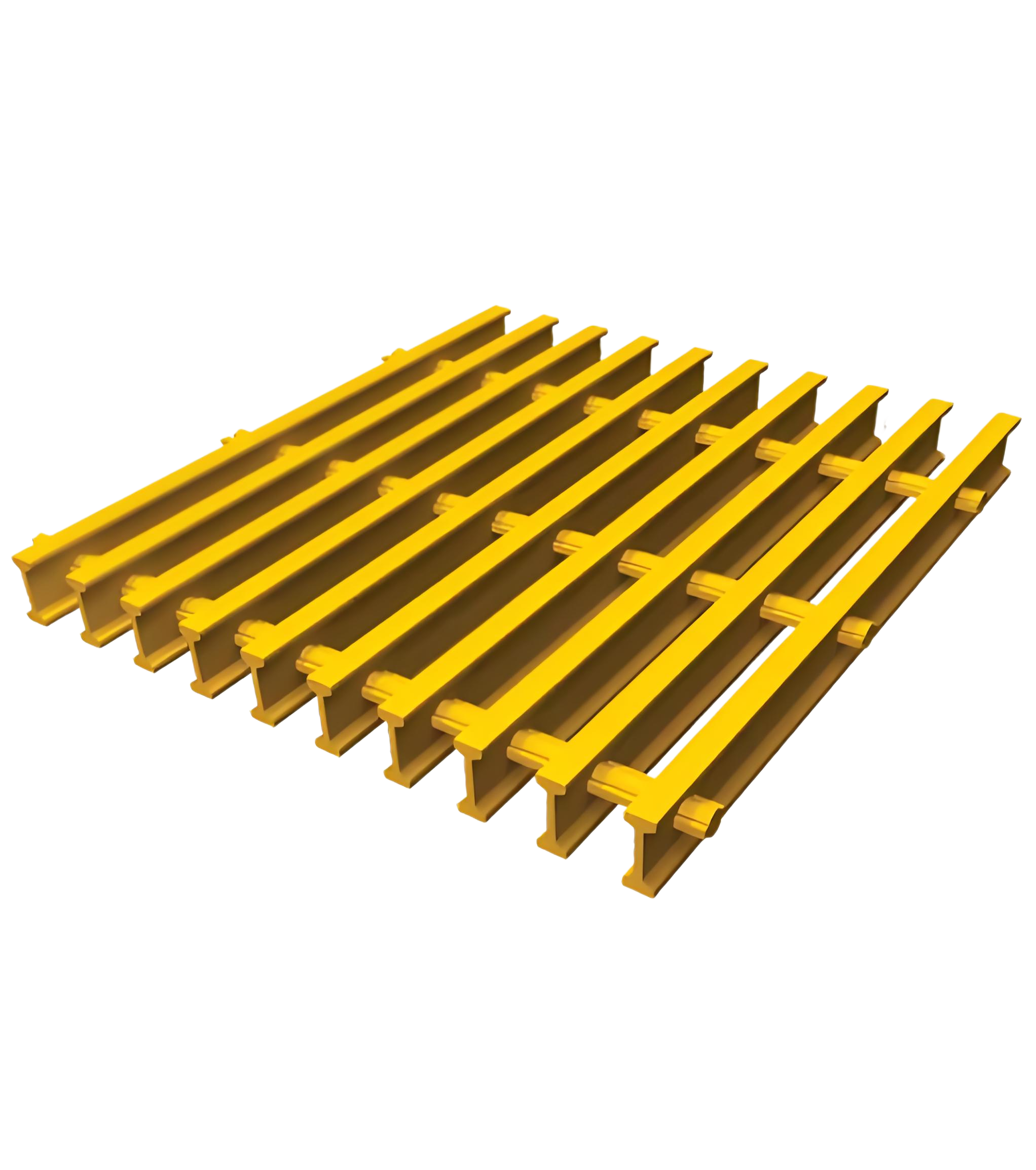

FRP pultruded grating is a structural material made of fiberglass reinforced plastic (FRP) through pultrusion. It uses glass fiber as a reinforcing material and resin as a matrix. After pultrusion through a specific mold, it forms a plate or profile with a uniform grating structure. In order to improve certain properties of pultruded gratings, such as UV resistance, wear resistance, flame retardancy, etc., various fillers and additives are usually added, such as alumina, titanium dioxide, flame retardants, etc. There are many common specifications, with different sizes of bearing bar spacing ranging from 25mm to 50mm, and there are also many options for crossbar spacing. The thickness is generally between 25mm and 50mm. In terms of shape, there are standard square gratings and special-shaped gratings customized according to special needs. In terms of color, it can be diversified according to the color paste. Common colors are yellow, green, gray, etc. Among them, yellow is often used in warning areas, green is more beautiful and suitable for landscape-related places, and gray is more general.

Core Materials

Reinforcement materials: Mainly alkali-free glass fibers, including resins, yarns, etc. Provide strength and stiffness of the grating. The direction and distribution of the fibers are critical to performance.

Matrix materials: Unsaturated polyester resin is the most commonly used. Depending on the application requirements, vinyl ester resin (stronger corrosion resistance), epoxy resin (better mechanical properties) or modified resin (such as flame retardant resin, weathering resin, etc.) can also be selected. The resin binds the fibers into a whole and imparts corrosion resistance, weathering resistance and other properties.

Fillers/Additives: Mineral fillers (to reduce costs and improve processability), color pastes (to provide color), flame retardants, UV stabilizers, etc. may be added to meet specific performance requirements.

Manufacturing process - Pultrusion

Glass fiber pre-impregnation: Select high-quality glass fibers and immerse them in an impregnation tank containing resin and additives. In this process, the glass fibers are fully coated with the matrix material, just like putting on a layer of solid "armor" to ensure that they can be closely combined with the resin in subsequent processing, providing a strong reinforcement for the product. For example, the use of alkali-free glass fibers can significantly improve the overall performance of the grid due to its good chemical stability and high strength.

Pultrusion molding: The pre-impregnated fibers are pulled through a carefully designed mold. The shape and size of the mold accurately determine the structure and specifications of the grid. During the pultrusion process, the fibers and resin are subjected to continuous pressure and appropriate temperature in the mold. Just like in a precise "shaping factory", the raw materials are gradually cured and formed into the required grid shape according to the settings of the mold. Whether it is a standard square grid or a specially designed special-shaped structure, it can be accurately manufactured.

Curing and cooling: During the pultrusion process, the high temperature causes the resin to undergo a curing reaction, so that the grid gradually acquires a stable shape and strength. Subsequently, after being processed by the cooling system, the grid quickly cools down to further stabilize its internal structure. This process is like turning a piece of soft dough into hard and fixed-shaped bread after baking and cooling, ensuring the quality and stability of the finished grille.

Cutting and post-processing: According to the design size, professional cutting equipment is used to accurately cut the initially formed grille to ensure that each product meets the actual use requirements. At the same time, the edges are polished to make the edges of the grille smooth to avoid scratches on people or other objects during use. For some scenes with anti-slip requirements, the friction of the surface is increased by methods such as adhesive sanding to improve the safety of the product.

Main Features And Advantages

Corrosion resistance: The selection of excellent isophthalic and vinyl resins makes FRP pultruded gratings have excellent corrosion resistance and can withstand corrosion from many gaseous and liquid media such as acids, alkalis, organic solvents and salts to varying degrees. For example, in the production workshops of chemical companies, which are frequently exposed to various chemical substances, the use of FRP pultruded gratings as operating platforms or trench covers can effectively resist chemical corrosion and greatly extend the service life of the facilities. Compared with metal gratings, they do not need to be replaced frequently, reducing maintenance costs.

Lightweight and high strength: Its density is only about one-fourth of that of steel, which is very easy to carry, thereby reducing transportation costs. At the same time, according to the weight ratio, resin accounts for about 35% and glass fiber accounts for 65%, giving it a very high strength/weight ratio. Taking offshore oil platforms as an example, the material needs to be as strong as possible to withstand the weight of various equipment and personnel while reducing its own weight as much as possible to reduce the overall load of the platform. FRP pultruded gratings have become an ideal choice.

Flame retardant: The oxygen index of general FRP pultruded grating is above 33, and the flame propagation rate (according to ASTM E-84 test) is less than 25, reaching the first-level flame retardant standard, while the oxygen index (GB8924) of phenolic pultruded grating is up to 100, the flame propagation rate of ASTM E-84 test is 5, and the smoke density is 10. In some places with strict fire protection requirements, such as power plants and refineries, the use of FRP pultruded grating with good flame retardant performance can effectively improve the safety of the place and reduce the risk of fire.

Impact and fatigue resistance: It has high impact strength and allows repeated bending without permanent deformation. Moderate elasticity makes people who work on it for a long time feel comfortable. For example, on the operating platform of some factories, workers walk or stand for a long time. The elasticity of FRP pultruded grating can reduce the tension of the workers' legs and backs, increase the comfort of work, thereby improving work efficiency, and conforming to the principle of ergonomics.

Anti-slip: The surface is pre-designed with linear anti-slip grooves, and the adhesive can also be sanded to increase the additional anti-slip effect. In some humid and greasy environments, such as the workshop floor of a food processing plant and the deck of a ship, anti-slip performance is particularly important, which can effectively prevent people from slipping and reduce accidents.

Aging resistance: Made of high-quality resin and glass fiber system, the product is guaranteed to have a service life of more than 20 years. After being exposed to the atmosphere, although the appearance may change, the strength can still be retained at more than 85% after 20 years. For facilities used outdoors for a long time, such as drainage ditch covers in municipal projects and noise barriers on highways, the aging resistance of FRP pultruded grating enables it to withstand the test of time and environment and maintain stable performance.

Beautiful and easy to maintain: The color paste is blended into all resins, with bright colors, not easy to fade, no paint required and self-cleaning. In some places where the environment is required to be beautiful, such as pedestrian walkways in urban parks and platforms in commercial plazas, FRP pultruded grating can not only provide practical functions, but also add beauty to the environment, and daily maintenance is simple, and only regular cleaning is required to maintain a good appearance.

Safety: Like molded grilles, it has excellent electrical insulation, no electromagnetic properties, and no electric sparks. It is very safe to use in work areas with conductive hazards, equipment sensitive to magnetism, and flammable and explosive places. For example, in electronic equipment production workshops, gas stations and other places, its safety features can effectively avoid safety accidents caused by static electricity or electric sparks.

Application Fields (extremely wide)

Chemical plant: In chemical plants, FRP pultruded grating is often used in stair treads, operating platforms, guardrails, double-layer floors, trench covers, filter gratings and other parts. Because there are a lot of corrosive chemicals in chemical plants, traditional metal materials are easily corroded and damaged, and the corrosion resistance of FRP pultruded grating enables it to be used stably and for a long time in such harsh environments, ensuring production safety and normal operation of facilities.

Power plant: FRP pultruded grating is used in trench covers, wastewater tanks and other areas of chemical water workshops. The chemical water workshop of the power plant involves the treatment of chemical substances such as acids and alkalis. The water quality in the wastewater tank is complex and corrosive. The corrosion resistance, anti-slip and insulation characteristics of FRP pultruded grating make it an ideal material choice for these areas.

Metal surface treatment plant: It is widely used in pickling liquid places, around machines to replace wooden floors, around highly corrosive containers, electroplating line walkways, double-layer floors and other locations. In the process of metal surface treatment, a large amount of strong acid and alkali chemicals are used, which places extremely high demands on materials such as the ground and operating platform. FRP pultruded grating can effectively resist chemical corrosion, and its high strength can withstand the weight of equipment and personnel.

Municipal Engineering:

Water treatment: maintenance walkways, manhole covers, large containers, washers, trash racks, water troughs, biochemical water treatment pool hangers, ventilation windows, stairs, cooling tower operating table paving, etc. In water treatment facilities, the pH value of water varies greatly and is in a humid environment for a long time. The corrosion resistance, anti-skid and light weight of FRP pultruded grating enable it to adapt well to these environments, making it convenient for staff to inspect and maintain, while extending the service life of the facilities.

Urban roads and bridges: In some cities, FRP pultruded grating is used in the ground paving of pedestrian overpasses and underground passages, as well as in the maintenance passages of bridges, etc., because of its light weight, high strength, beautiful appearance and durability. For example, the use of FRP pultruded grating as a bridge deck paving material on pedestrian overpasses can not only reduce the weight of the bridge itself, but also improve the pedestrian experience and safety through its diverse colors and good anti-skid performance.

Transportation facilities:

Offshore oil platform: Since the platform is in the marine environment, it faces problems such as seawater corrosion, sea breeze erosion, and high loads on equipment and personnel. The light weight, high strength, corrosion resistance, and fatigue resistance of FRP pultruded grating make it an important material for operating platforms, stair treads, walkways and other parts of the platform. It can not only meet the platform's requirements for structural strength, but also effectively resist the erosion of the harsh marine environment and reduce maintenance costs.

Ship: FRP pultruded grating is widely used on the deck of the ship, the passages in the cabin, the operating area and other locations. During the voyage of the ship, the deck is exposed to seawater and humid air for a long time and is prone to corrosion. The corrosion resistance and anti-skid properties of FRP pultruded grating can ensure the safety of the crew walking and working on the ship, while reducing the weight of the ship itself and improving fuel economy.

Construction industry:

Inside buildings: In some commercial buildings or industrial plants, such as platforms between floors, stair steps, equipment operation platforms, etc., FRP pultruded grating can be used as an alternative to steel or wood materials. Its light weight and high strength make it easy to install, and its corrosion resistance can cope with some possible chemical erosion, and its aesthetics can also meet certain architectural decoration needs.

Building facades: FRP pultruded gratings are used for facade decoration or maintenance channels of some buildings. For example, the facade inspection channels of some high-rise buildings use FRP pultruded gratings, which are convenient for staff to clean and maintain the facades, and because of its good weather resistance, it can maintain stable performance under long-term wind, sun and rain.

Agriculture and aquaculture:

Aquaculture: FRP pultruded gratings are widely used in the surrounding walkways of aquaculture ponds, the covers of aquaculture ponds, etc. In aquaculture environments, the water contains various microorganisms and chemicals, and is in a humid state for a long time, and traditional materials are prone to rot and damage. The corrosion resistance of FRP pultruded grating enables it to adapt to this environment, and its anti-slip performance ensures the safety of farmers during operation.

Agricultural greenhouse: In agricultural greenhouses, it is used for passages for people to walk, platforms for equipment to be placed, etc. FRP pultruded grating provides convenience for greenhouse operations due to its light weight, corrosion resistance, and easy cleaning. For example, using FRP pultruded grating as a passage in a greenhouse makes it convenient for workers to walk in a humid environment, and it will not be affected by rust and other problems.

Precautions For Purchase And Use

1. Application scenario:

◦ What is the specific use? (For example: chemical plant platform, sewage treatment plant walkway, offshore platform, cooling tower fence, trench cover, stair treads, equipment platform, non-slip floor, livestock pen floor, etc.)

◦ Environmental exposure conditions: What chemicals are exposed to (name, concentration, temperature)? Is there UV exposure? What is the humidity? Temperature range? Is there continuous physical impact or wear?

◦ Safety requirements: Is a specific anti-slip level required? Is a flame retardant/fireproof level required? Is electrical insulation required?

2. Load requirements (most critical!):

◦ Expected load type: Is it pedestrian traffic? Carts/small vehicles? Forklifts? Heavy equipment? Static equipment?

◦ Maximum concentrated load: What is the maximum weight that a single point or small area may bear? (For example: forklift wheel pressure)

◦ Uniformly distributed load: What is the pressure evenly distributed across the entire area? (e.g. multiple people standing or stacking materials)

◦ Span: What is the distance between the support beams under the grating? Span is one of the most important factors in determining the thickness and structural strength of the grating. Be sure to provide accurate support spacing!

3. Dimensions:

◦ The length and width of the required coverage area.

◦ Grating plate thickness: Mainly determined by the load requirements and span.

◦ Mesh size (porosity): How big the opening is required? This affects the drainage/chip removal efficiency, skid resistance, and whether it meets the requirements for small objects falling (such as tools, mobile phones, etc.).

Commonly used meshes: 19x19mm, 25x25mm, 30x30mm, 38x38mm, 50x50mm, etc. The smaller the mesh, the higher the load capacity is usually, and the better the protection against small objects falling, but the drainage and chip removal efficiency may be slightly lower and the cost is slightly higher.

◦ Surface type:

Standard sand surface: Provides good skid resistance and is economical and commonly used.

Grooved surface: The surface has grooves, which provides stronger anti-slip properties, especially suitable for ramps, wet environments or oily environments.

Patterned cover: A dense patterned plate is molded on the surface of the grille to completely close the pores, providing the smoothest and easiest to clean surface (suitable for places with high hygiene requirements such as food and medicine), while maintaining anti-slip properties, but the cost is the highest.

4. Aesthetic requirements (if applicable):

◦ Is a specific color required? (Common colors: green, gray, yellow, black, etc. The color is usually determined by the color paste in the resin and has little effect on the performance, but the weather resistance/chemical resistance of the color paste needs to be confirmed).

◦ Are there any special requirements for the surface appearance?

5. Budget range:

◦ Set reasonable budget expectations. The initial cost of FRP grating may be higher than that of ordinary steel grating, but its ultra-long service life and extremely low maintenance cost (no anti-corrosion coating required) usually result in lower overall costs.

Resin Type

FRP Grating Surface Type

It's flat and smooth, with no grain or texture, and feels like hard plastic.

Safe and anti-slip by embedding wear-resistant particles on the grating surface

The design with regular depressions enhances anti-slip and drainage performance.

The surface particles form a uniform and dense rough surface

FRP Pultruded Grating Specifications

Specification of FRP Pultruded Grating ( I-Type)

Specification of FRP Pultruded Grating ( T-Type)

Product Benefits

A: FRP grating is a grid-like plate made of glass fiber as reinforcement material and unsaturated polyester resin as matrix through special process. It has the characteristics of corrosion resistance, light weight and high strength, flame retardant, insulation, anti-slip, etc., and is widely used in chemical industry, electric power, sewage treatment, platform walkway and other scenes.

A:

1. Dimensions (length, width, and thickness)

2. Load requirements (such as vehicle tonnage)

3. Operating environment (corrosive media/temperature)

4. Surface type (glossy/sanded)

5. Color and flame retardant requirements

A: Conventional colors (yellow, gray, green) do not affect strength, but dark colors (such as black) are better for UV resistance and are recommended for long-term outdoor use.

Are you looking for a reliable FRP Grating and Moulding supplier?

As a high-quality supplier who has been deeply involved in the FRP industry for many years, we focus on the research and development and production of FRP gratings, FRP pultruded gratings, FRP pultruded profiles and matching FRP grating molds. With advanced technology, stable quality and professional services, we have become a long-term partner of many engineering companies, equipment manufacturers and end users.If you are looking for a stable, professional and reliable FRP product supplier, please contact us! We will provide you with the most competitive products and services to help your project land successfully!